Industrial Application of Ceramic Ball Valve

Product description of Ceramic Ball Valve

Ceramic ball valve adopts high-tech new ceramic structural materials to make the sealing parts and vulnerable parts of the valve, which improves the wear resistance, corrosion resistance and sealing of the valve products, and greatly extends the service life of the valve. The use of ceramic valves can greatly reduce the number of valve maintenance and replacement, improve the safety and stability of the supporting equipment operation system, and save equipment repair costs.

Features of Ceramic Ball Valve

1. All parts in contact with the medium are structural ceramic materials, with extremely high chemical stability and hardness (Rockwell hardness hrc90), second only to diamond. Therefore, this valve has extremely high wear resistance, corrosion resistance, erosion resistance, good heat insulation and small thermal expansion.

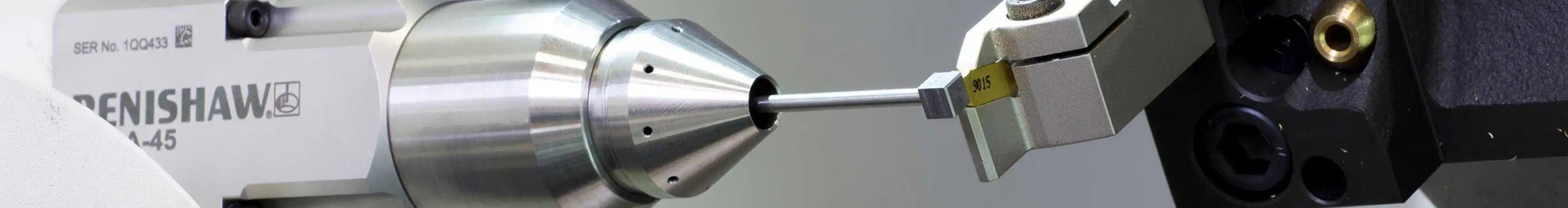

2. The ball is manufactured by advanced grinding equipment and technology, with high roundness accuracy and good surface quality. After being grinded with the valve seat, good sealing performance can be achieved by using the self lubricity of Zr02 ceramics.

3. It completely changes the shortcomings of metal hard seal ball valve, such as easy leakage, large torque and non corrosion resistance of sealing surface.

4. The good wear resistance of ceramics makes this valve durable and highly reliable Long service life, 2-4 times that of titanium alloy valve and Monel valve.

5. Used in granular media with high hardness, or media with soft particles but corrosion, this kind of valve has incomparable absolute advantages and is the only valve suitable for this kind of media.