Segment Ball Valve Installation Manual

Product description of Segment Ball Valve

Segment ball valve is a kind of rotary ball valve with metal core seat or metal to Teflon sealing fit. It combines the control characteristics of ball valve and butterfly valve into one, which can be used as both control valve and shut-off valve. Segment ball valve is a fluid that needs to have flow regulation function and the medium in the working condition is impurity particles. The hemisphere has no flow regulation function, and can also be used under the fluid condition with impurity particles.

Installation of Segment Ball Valve

1. Cleaning of Segment ball valve - when overhauling the valve disassembled from the process pipeline, all the parts on it impregnated with process medium must be cleaned. In order to avoid the loss of people and equipment caused by some corrosive or other harmful fluids. At the same time, the rust on the exposed surface of parts shall be removed.

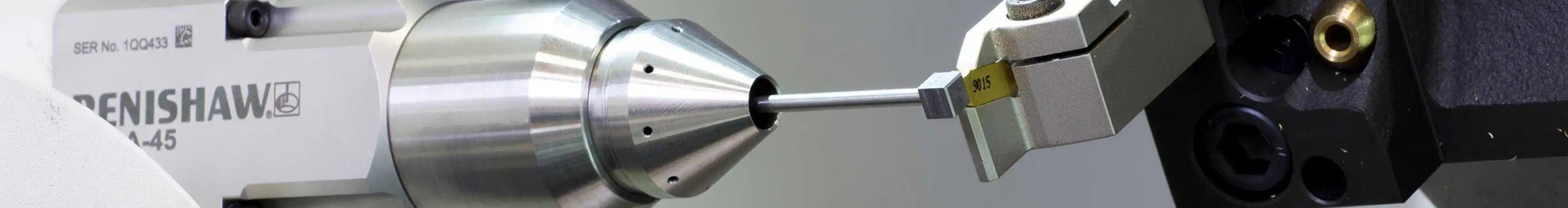

2. Disassembly of Segment ball valve - in order to inspect all parts and components to determine the scope of repair and replacement. First, the actuator and valve should be completely removed. During disassembly, the precision machined parts such as valve core, valve seat, valve rod, push rod, shaft sleeve and the precision machined surface of all parts must be protected to prevent damage, so as to reduce the maintenance cost. Special tools should be used to disassemble the valve seat.

3. Maintenance of main parts - if there are small rust spots and wear on the throttling surface of the valve core and the sealing surface of the valve core and valve seat. It can also be repaired by general machining and grinding methods. If the damage is serious, new parts must be replaced. During repair, it is required to ensure the coaxiality of valve core and valve seat. If the sealing surface of the valve rod is damaged, it can only be replaced with new parts.Damage to the guide and sealing surface of the push rod. The reaction actuator must be replaced with new parts. The positive action actuator can be properly repaired.Cracks and other defects affecting the strength of the compression spring are found during maintenance. It must be replaced with a new one.

4. Replacement of vulnerable parts - the vulnerable parts of this V-shaped ball valve are mainly: packing, O-ring seal, gasket, diaphragm and other parts. The removed packing, O-ring and gasket shall be replaced with new parts during each maintenance. After the diaphragm is removed, it is necessary to check whether there are any cracks, aging and wear marks that indicate possible cracking, and then decide whether to replace them according to the specific situation. Generally, it must be replaced within 2 ~ 3 years.

5. Assembly and commissioning - during assembly, proper grease should be applied to the positioning parts, guide parts and threaded connection parts of parts to facilitate the next overhaul and disassembly. In addition, special attention should be paid to the coaxiality of the push rod, valve core components and valve seat in the whole machine.

After the completion of assembly and commissioning, the product must pass the factory test items specified in the standard before continuing to be installed and used.