Top Entry Ball Valve

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange,Welding

Feature: Top entry for easy maintenance

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange,Welding

Feature: Top entry for easy maintenance

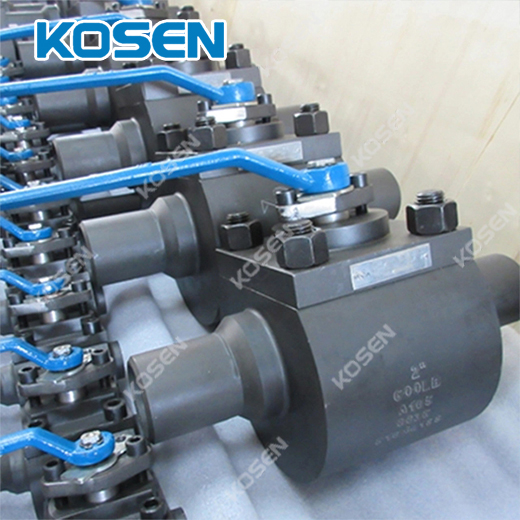

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: A105 LF2 F304 F316 F316L or others

Connection: Flange,Welding

Feature: Forged steel, top entry,trunnion mounted

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange

Feature: For high pressure medium

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top Entry

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange,Welding

Feature: Quick dissemble and quick maintain

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -46℃ ~ 121℃

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange,Welding

Feature: Quick dissemble and quick maintain

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top Entry

Medium: Water,steam,oil,gas,etc.

Temperature: -46℃~ 121℃

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange,Welding

Feature: Quick dissemble and quick maintain

Port size: 2"~24" (DN50~DN600)

Pressure: CL150-CL2500

Structure: Top entry,trunnion mounted

Medium: Water,steam,oil,gas,etc.

Temperature: -20~150ºC, -40~450ºC

Body material: WCB, A105, LCB, LF2, CF8, F304, CF8M, F316, etc

Connection: Flange

Feature: For high pressure medium

Product description of Top Entry Ball Valve

The top mounted ball valve includes a valve body, a wedge-shaped ball, a valve seat, a bonnet, and a valve rod. The side wall of the valve body is provided with a wedge-shaped ball mounting hole with an upward opening. The valve rod is linked with the wedge-shaped ball, and a spring is sleeved at the lower part of the valve rod. The spring takes the wedge-shaped ball as the first base, the boss set on the valve rod as the other base, and a seal is set between the upper end of the boss of the valve rod and the bonnet, A sealing gasket is arranged between the valve cover and the valve body. The cross section of the seal is wedge-shaped. A wedge-shaped sealing fit is formed between the boss or the valve cover and the seal. The wedge-shaped sealing fit is formed between the wedge-shaped seal and the sealing face, which is well arranged on the upper end face of the boss and is used to seal the wedge-shaped seal between the valve stem and the valve cover by using the elastic force of the spring or the pressure force of the medium, The wedge principle is used to make the sealing surface tighter and the sealing effect better.

Features of Top Entry Ball Valve

1. Small pressure loss: when fully opened, the water loss is zero, and the flow channel is completely unblocked; The internal organs are automatically cleaned, the valve core rotates 90 degrees, and the inner cavity of the valve body is automatically flushed to clean the sundries in the medium and the medium will not be deposited in the valve cavity. The sphere is hemispherical, and the circulation has a high CV value, which enhances the system efficiency of the pump and reduces the abrasion to a low level.

2. Resistance to particle wear: using the principle of double eccentricity, during the closing process, the ball only leans towards the valve seat at the last moment, without friction; And the sealing ring on the valve seat is overlaid with wear-resistant self-lubricating alloy, which is not easy to wear and scour; The ball crown of the knife shaped ball mouth and the valve seat have the functions of wiping, cleaning and shearing, and are not easy to scale.

3. The automatic compensation seal is reliable: when the pressure is positive, the more the ball and the valve seat are closed, the tighter the eccentric principle is used, so as to get a good seal: when the floating valve seat is under pressure, the valve seat will automatically push closer, and the higher the pressure is, the tighter the valve seat will push closer to the ball, so as to get a good seal; It can maintain a lasting tight seal and adapt to harsh working conditions. Under long-term use, if the valve seat seal is worn or damaged, the valve seat will automatically push against the ball under the action of spring, so as to get a good automatic compensation function.

4. Suitable for high velocity media: because the ball is hidden on one side of the valve cavity, it forms a straight passage without flow resistance. The solid eccentric fixed crankshaft has no vibration and noise in high velocity media.

5. Long service life and easy switching: there are no vulnerable parts. Due to the effect of eccentricity, the sealing surface of the ball and the valve seat is completely separated during the opening and closing of the valve, so that there is no scratch between the valve seat surface and the spherical surface of the ball crown, and the friction free rotation is made, which effectively reduces the operating torque torque torque, and the operation is light; The automatic compensation function of the valve greatly improves the service life of the valve.

6. Convenient maintenance: the valve is top mounted, and the ball crown and supporting ball are installed from the upper part of the valve; During maintenance, it is only necessary to open the valve cover and lift out the ball crown and support ball to carry out maintenance and seal rings and other accessories. It is not necessary to remove the whole valve from the pipeline, which brings great convenience to underground pipelines, especially industrial ball valves.

7. The ball valve can retain the medium in the pipeline as appropriate during the maintenance operation, which will not cause a waste of energy; This will exempt the user from many preliminary auxiliary work and make the maintenance simpler.

8. On some specific occasions, this valve can not affect the normal operation of the pipeline system during the rush repair. As long as the upper opening is quickly closed after the ball assembly is taken out, the pipeline can be immediately restored to the pressure operation, so that the benefit loss caused by the rush repair valve can be reduced to a small extent.

Industrial applications of Top Entry Ball Valve

Top mounted ball valves are widely used in oil and natural gas pipelines, as well as oil extraction, oil refining, petrochemical, chemical, chemical fiber, metallurgy, electric power, food, paper and other devices. The top mounted ball valve is easy to disassemble and maintain on the pipeline. When the valve fails on the pipeline and needs to be repaired, it is not necessary to disassemble the valve from the pipeline. Just remove the middle flange bolts and nuts, remove the bonnet and stem assembly from the valve body, and then take out the ball and seat assembly. The ball and valve seat can be repaired online. This kind of maintenance saves time and reduces the loss to a low point.